Routing Operations Form

To use the Operations form, firstly position your cursor on the row you wish to contain the routing data. Then double-click in one of the cells in the Operations section and the form will automatically load. Alternatively click on the ‘Forms’ icon and select ‘Operations’ on the Routing Wizard ribbon.

Prerequisites

Organization and Item information must exist in the spreadsheet.

Routing Alternate information must exist in the spreadsheet.

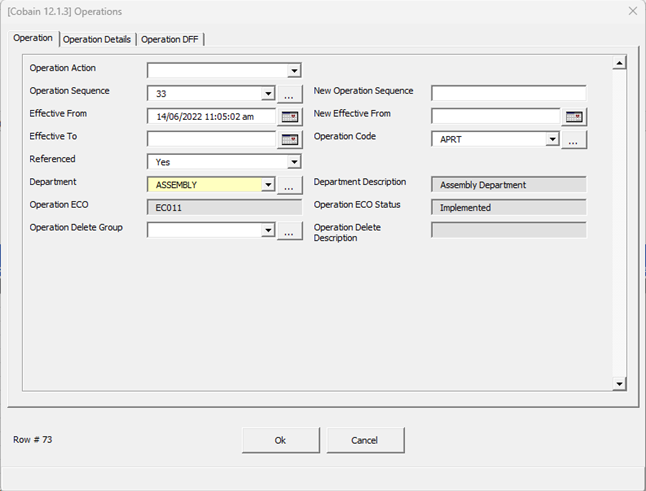

The following is an example of the Engineering Operations form:

Operations Tab

Operation Action - The list of values contains the upload actions available for the Operations section.

Operation Sequence – When creating a routing enter in an Operations Sequence number. When performing an update, select an existing Operations Sequence number.

New Operation Sequence – If you want to change an Existing Operation Sequence number, enter a new Operation Sequence in this field. Use this field with an ‘Update’ action.

Effective From – This field is required for Create and Update. Note this is time sensitive so you have to be accurate to the second.

New Effective From – If you want to change an existing Effective From Date, enter the new Effective From Date in this field. Us this field with an ‘Update’ action.

Effective To – Enter or select an Effective To Date/Time using the calendar. (Disable Date).

Operation Code - The list of values contains all available codes for Standard Operations.

Referenced – A Yes/No flag controlling whether you can change the information from a Standard Operation.

Department – The list of values contains all Departments available in the Organization, or the Department to which the selected Operation Code belongs. You can only change the Department on existing routings if there are no resources for that Department on the routing operation number.

Operation Description – Enter a customized description.

Operation Delete Group – The list of values contains all Operation Delete Groups available to the Organization.

Operation ECO - Displays the ECO (if any) acting on the Operation - Not on the Manufacturing Routing Operations form.

Operation ECO Status- Displays the status of the ECO (if any) acting on the Operation – This field is not on the Manufacturing Routing Operations form.

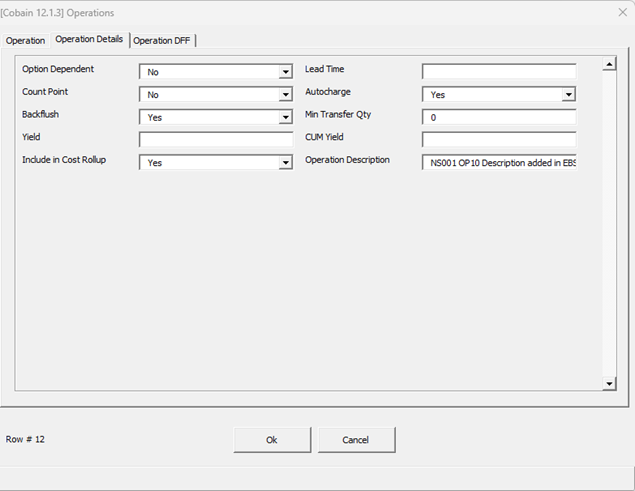

Operation Details Tab

Option Dependent - A Yes/No flag controlling Operations in ATO model or Option Class Routings only. Indicate whether the Operation is Option Dependent, that is, whether the Operation is dependent on the choice of an optional component. All mandatory components and their related Operations appear on the routing for each configuration.

Lead Time - Enter the item’s manufacturing Lead Time percent required to complete all previous operations on the routing.

Count Point, Auto Charge and Backflush - Yes/No flags controlling WIP transactions.

Min Transfer Qty – Enter the number of assemblies to move from this operation to the next. The default is 0.

Yield, CUM Yield - If the routing is lot–based, then enter the yield and cumulative yield details.

Include in Cost Rollup – A Yes/No flag indicating whether the Operation will be included in the cost rollup.

Once you have entered your data click the:

‘OK’ button to transfer the information back to Excel.

‘Cancel’ button if you wish to revert to the values at the time you opened the form.

Refer to section: